… take precision to the highest level.

Highly precise radial and axial run out results.

And that’s standard.

The right and left hand insert system and the smooth cutting of the side milling cutters provide the stability essential for complying with highly precise radial and axial run out tolerances. For a wide range of work piece specific challenges requiring the attainment of maximum precision and … maximum Q.

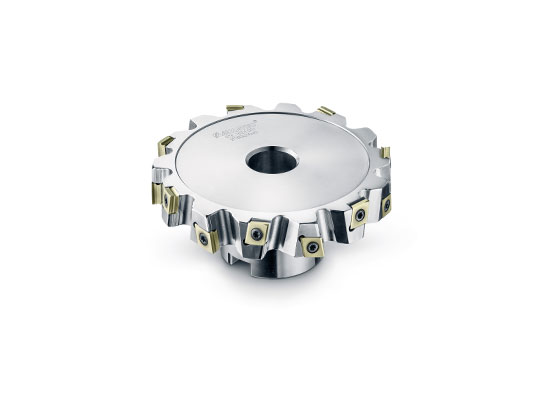

Side milling cutters and slot milling cutters

Typen

Side milling cutters tangential CB18 | CN18

- 4-cutting edge CN indexable insert

- Fine tooth pitch through tangential insert design

- Very smooth cutting through left and right hand inserts

- Secondary cutting edge positioned outside of the cutting zone

- Face milling possible with CB18

| Width of cut | 10 – 14 mm |

| Kappa angle + groove machining | 90° |

| Diameter | 100 – 160 mm |

| ae Width of cut | 25 – 52 mm |

| hmax | 0.10 – 0.20 mm |

Side milling cutters tangential EB18

- 4-cutting edge EN indexable insert

- Fine tooth pitch through tangential insert design

- Very smooth cutting through left and right hand inserts

- The secondary cutting edge ispositioned outside of the cutting zone

- Face milling possible

| Width of cut | 14 – 24 mm |

| Kappa angle + groove machining | 90° |

| Diameter | 125 – 250 mm |

| ae Width of cut | 32 – 78 mm |

| hmax | 0.08 – 0.25 mm |

Side milling cutters tangential EN18

- 4-cutting edge EN indexable insert

- Fine tooth pitchthrough tangential insert design

- Very smooth cutting through left and right hand inserts

- The secondary cutting edge positioned outside of the cutting zone

| Width of cut | 14 – 24 mm |

| Kappa angle + groove machining | 90° |

| Diameter | 125 – 200 mm |

| ae Width of cut | 32 – 78 mm |

| hmax | 0.08 – 0.25 mm |

Side milling cutters TB18

- Extremely smooth cutting through left and right hand inserts

- Highly precise widths of cut from 4-12 mm

- Complies with narrow radial and axial run out tolerances

- 3-side embedding of the T-style indexable insert

| Width of cut | 4 – 12 mm |

| Kappa angle + groove machining | 90° |

| Diameter | 63 – 160 mm |

| ae Width of cut | 13 – 44 mm |

| hmax | 0.05 – 0.16 mm |

Side milling cutters TN18

- Extremely smooth cutting through left and right hand inserts

- Highly precise widths of cutfrom 4-12 mm

- Complies with narrow radial and axial run out tolerances

- 3-side embedding of the T-style indexable insert

| Width of cut | 4 – 12 mm |

| Kappa angle + groove machining | 90° |

| Diameter | 63 – 160 mm |

| ae Width of cut | 12 – 89 mm |

| hmax | 0.56 – 0.16 mm |

Slot milling cutters GN18

The GN18 is a standard milling cutter. It slits and severs. It has double-cutting edge indexable inserts that are positively connected. This makes the GN18 extraordinarily reliable. And fast. Moreover, it boasts a compact design. To accommodate more teeth. They deliver… more Q.

- 2-cutting edge indexable insert

- Cutting width from 2.5 mm

- Excellent cutting force dissiption

- Narrow tooth pitch

- High feed rates

| Diameter | 80 – 160 mm |

| Width of cut B(h11) | 2 – 3.5 mm |

| Zeff | 8 – 24 |

| ae Width of cut | 18 – 44 mm |

Tool Program | Technical Data

All data and facts are included in our catalogue: